Heating Spigots and Bushes

There are DVS standard sockets & spigtos , IPS sockets , repairing sockets , full range of weld-in saddle sockets in FUYI TOOLS.

DVS Standard Sockets & Spigots Size:

|

16mm |

75mm |

|

20mm |

90mm |

|

25mm |

110mm |

|

32mm |

125mm |

|

40mm |

140mm |

|

50mm |

160mm |

|

63mm |

There are thirteen sizes. |

IPS SOCKETS:

|

1/2" |

1-1/4" |

|

3/4" |

1-1/2" |

|

1" |

2" |

The Size of weld-in Saddles as following

D40/25、D50/25、D63/25、D75/25、D90/25、D110/25、D125/25、D140/25、D160/25

D63/32、75/32、D90/32、D110/32、D125/32、D160/32、D200/32、D250/32

D90/40、D110/40、D125/40、D160/40、D200/40、D250/40

D110/50、D125/50、D160/50、D200/50、D250/50

D125/63、D160/63、D200/63、D250/63、D315/63

D160/75、D200/75、D250/75、D315/75

D200/90、D250/90、D315/90

D200/110、D250/110、D315/110

D250/125、D315/215

D315/160

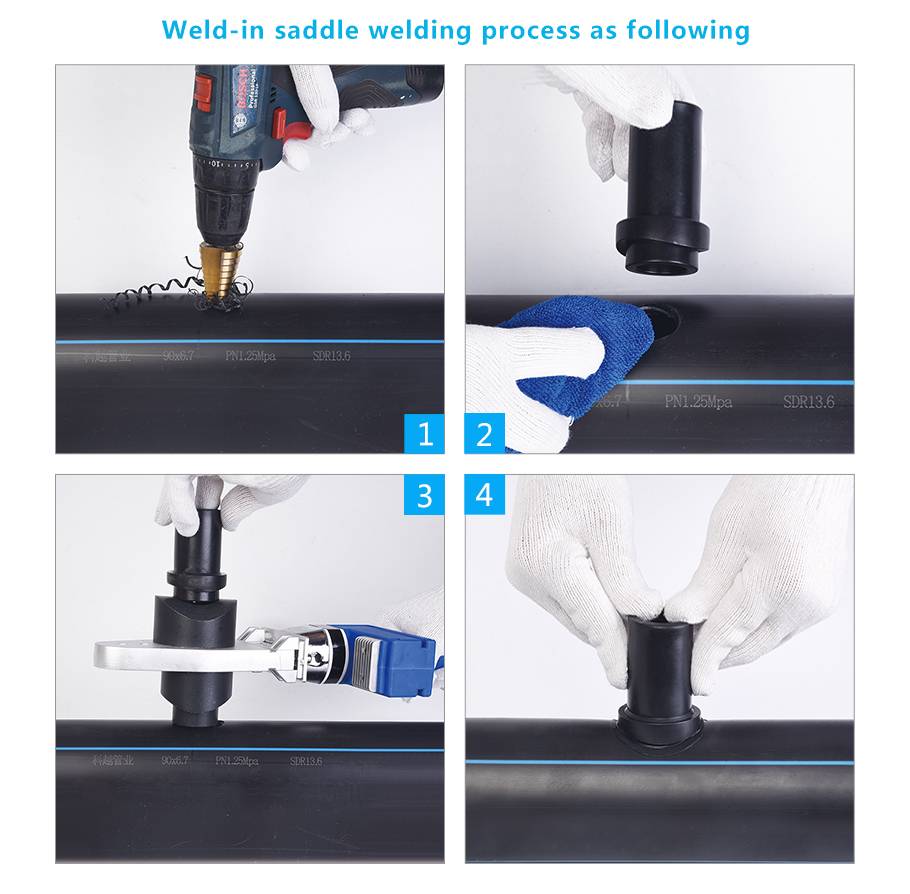

Weld-insaddle welding process as following:

1.Drilla hole though the pipe wall with the drill. Pay more attention on the depth ofthe drill.

2.Clean the hole with the piece of fabric or napkin. The welding surfaces have to beclean and dry. For stabi composite pipes remove the rest of the aluminumremaining at the drilled hole by chamfering the edge of the hole.

3.Once the socket welder is on, wait until the machine indicates the reaching of theworking temperature (260°±2°). Push the saddle heating tool with the spigotinto the pipe hole and the saddle into the other tool. Heat the pipe surfaceand the saddle for 30 seconds.

4.Once the hating process is over remove the socket welder ad push the saddles spigotinto the pipe hole with a light pressure until the surface meet entirely. Keeppressing for about 15-20 seconds. Let the joint cool down for 20 minutes beforemaking the pressure test.

Repairing Sockets:

7MM , 9MM and 11MM

Pipe Hole Repair Set:

Pipe accidently damaged by drilling , nail or screws , it can be repaired by means of pipe repairing set. It can reduced damage to walls or tiles.

Necessary Tools:

Fusion welding machine, pipe cutter , electric drill , piece of fabric or napkin for degreasing, scoket for repair stick , repair stick with 7mm ,9mm and 11mm diameter ends.

Repairing Steps as following:

1.Check the hole size. Damagedhole must be drilled again, the hole with diameter less than 6mm must bedrilled with 6mm drill and the hole with diameter from 6.5mm to 7.5mm must bedrilled with 8mm drill. The hole with diameter from 8.5mm to 9.5mm must bedrilled with 10mm drill.

2.Clean repair position with thepiece of fabric or napkin. The welding surface must clean and dry. Make surethat the water from the pipe is not in direct contact with the repairing area.

3.Choose the right repair stick,wait the working temperature reach (260°± 2°C ). Push therepair stick into the sockets , the special sockets into the pipe. Heat thehole and the stick for 5 seconds.

4. Take out the repair stick andremove the welder from the pipe, insert the heated repair stick into the heatedhole without turning. Wait for 15 seconds.

5. When the joint cools down, cutoff the rest repair stick ad keep it. The repair stick can be used on next time.