Hot Selling for 20-63mm Ppr Pipe Machine - Drill bit for weld in saddle – Fuyi

Hot Selling for 20-63mm Ppr Pipe Machine - Drill bit for weld in saddle – Fuyi Detail:

Plastic Pipe Hole Saw (Drill bit for weld-in saddle)

Special drill for perfect drilling of hole in the main pipe to mount weld-in saddles of all types.

It’s mainly used on PP-R pipe and HDPE pipe. This is necesssary tool to created the correct hole for making branch on the pipe.

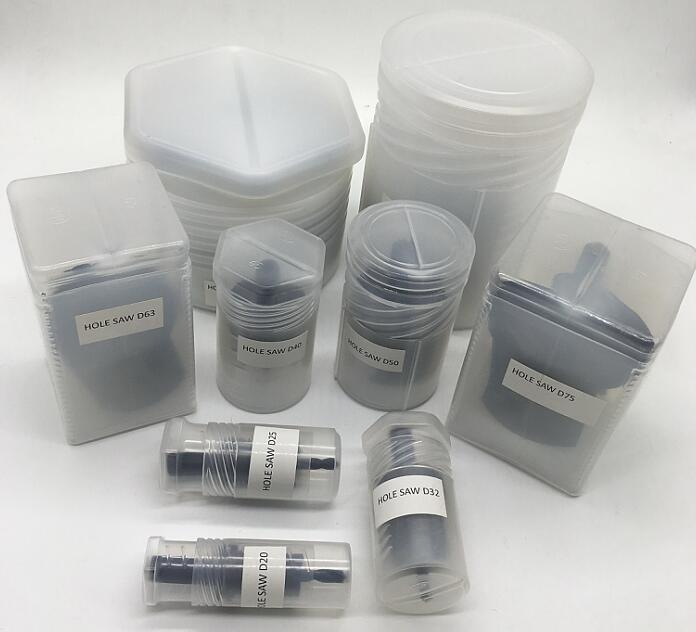

Hole saw is a professional tool before saddle welding. Our hole saw diameter from 20mm to 110mm.

The package of Plastic Pipe Hole Saw: Plastic Box as following

Steps For Using This Hole Saw:

1. Choose right hole saw according the diameter of the branch on the main pipe.

2. Fix the hole saw to the electric drill.

3. Drill the hole on the main pipe.

4. Pull the hole saw out and clean the surface of the hole.

Drill bit for weld-in saddles size as following:

| 20mm | 40mm | 75mm |

| 25mm | 50mm | 90mm |

| 32mm | 60mm | 110mm |

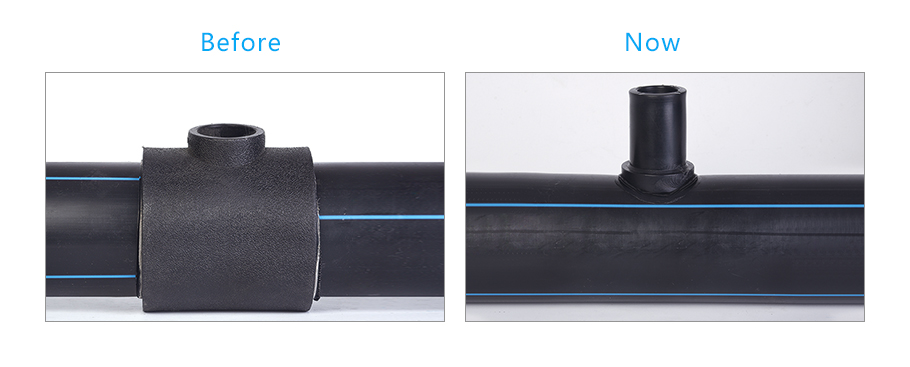

Weld-insaddle welding process as following:

1.Drilla hole though the pipe wall with the drill. Pay more attention on the depth ofthe drill.

2.Clean the hole with the piece of fabric or napkin. The welding surfaces have to beclean and dry. For stabi composite pipes remove the rest of the aluminumremaining at the drilled hole by chamfering the edge of the hole.

3.Once the socket welder is on, wait until the machine indicates the reaching of theworking temperature (260°±2°). Push the saddle heating tool with the spigotinto the pipe hole and the saddle into the other tool. Heat the pipe surfaceand the saddle for 30 seconds.

4.Once the hating process is over remove the socket welder ad push the saddles spigotinto the pipe hole with a light pressure until the surface meet entirely. Keeppressing for about 15-20 seconds. Let the joint cool down for 20 minutes beforemaking the pressure test.

Product detail pictures:

Related Product Guide:

The key to our success is "Good Product Quality, Reasonable Value and Efficient Service" for Hot Selling for 20-63mm Ppr Pipe Machine - Drill bit for weld in saddle – Fuyi , The product will supply to all over the world, such as: Seychelles, Saudi Arabia, Philippines, Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.